Flow Forming with internal splines

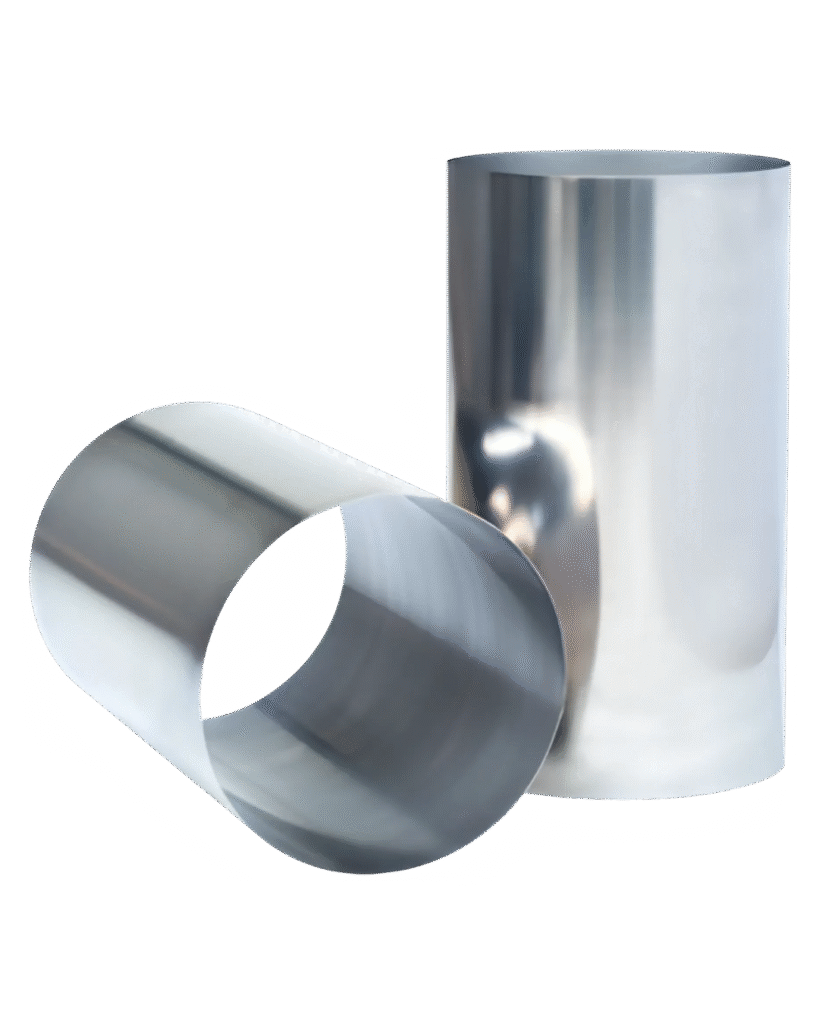

Flow Forming of cylindrical tubes

Shear forming

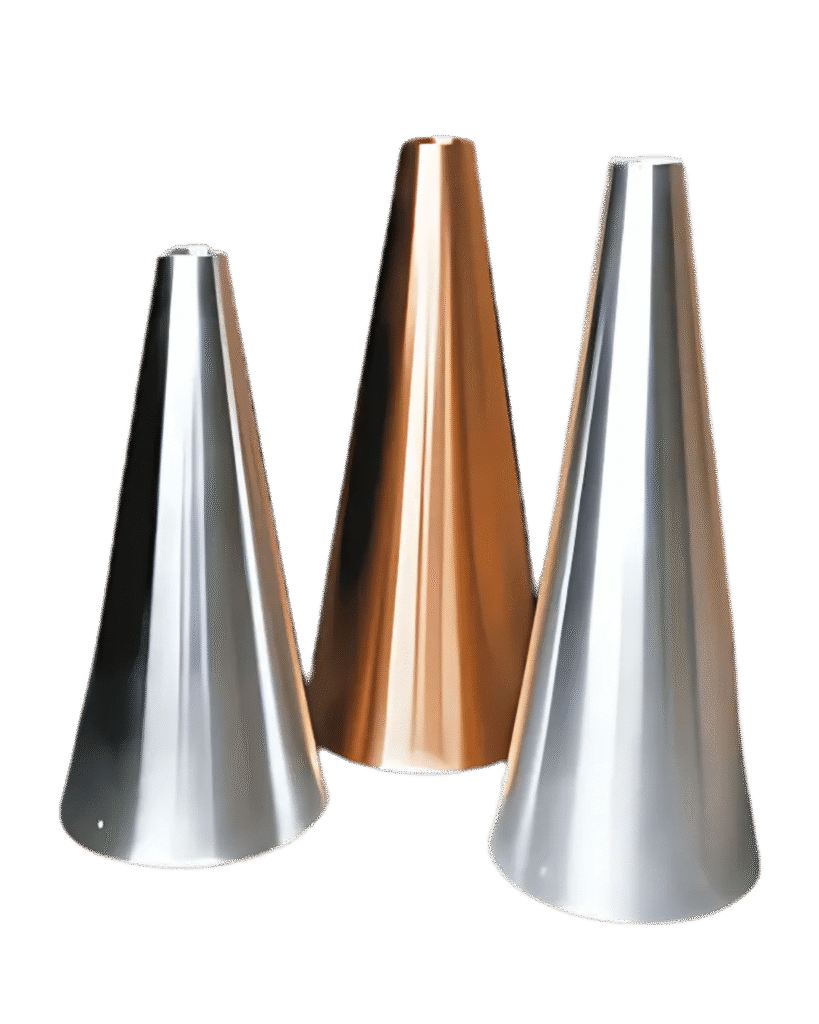

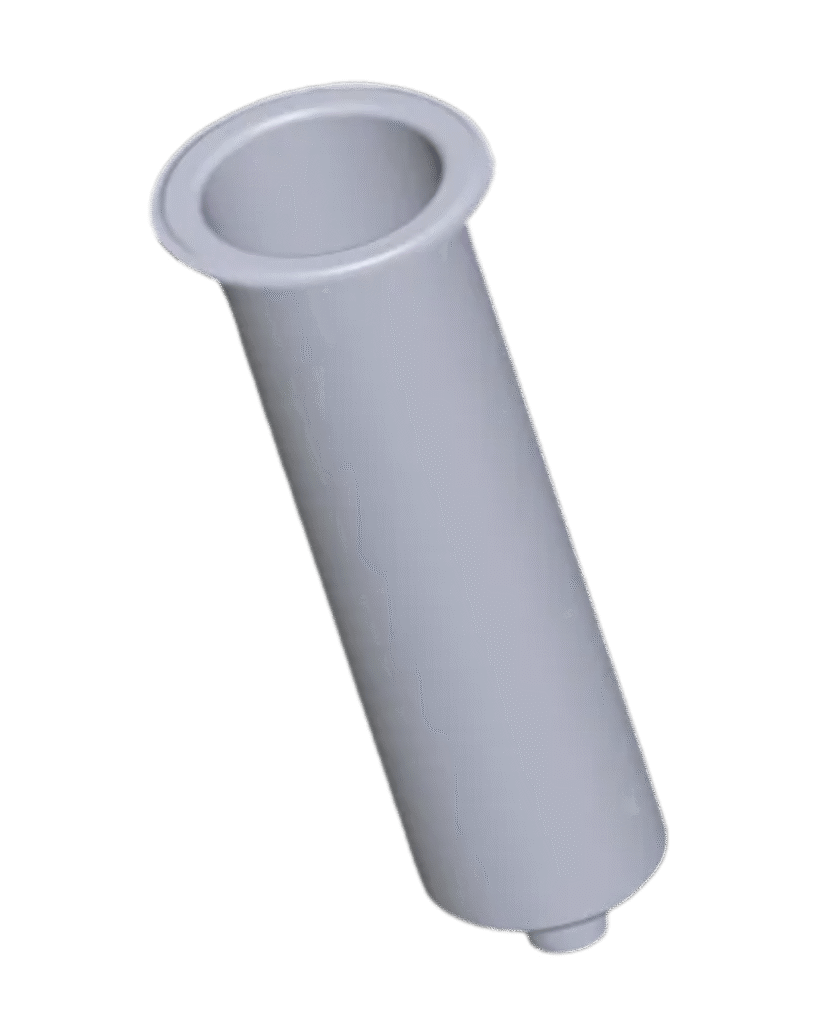

Metal spinning

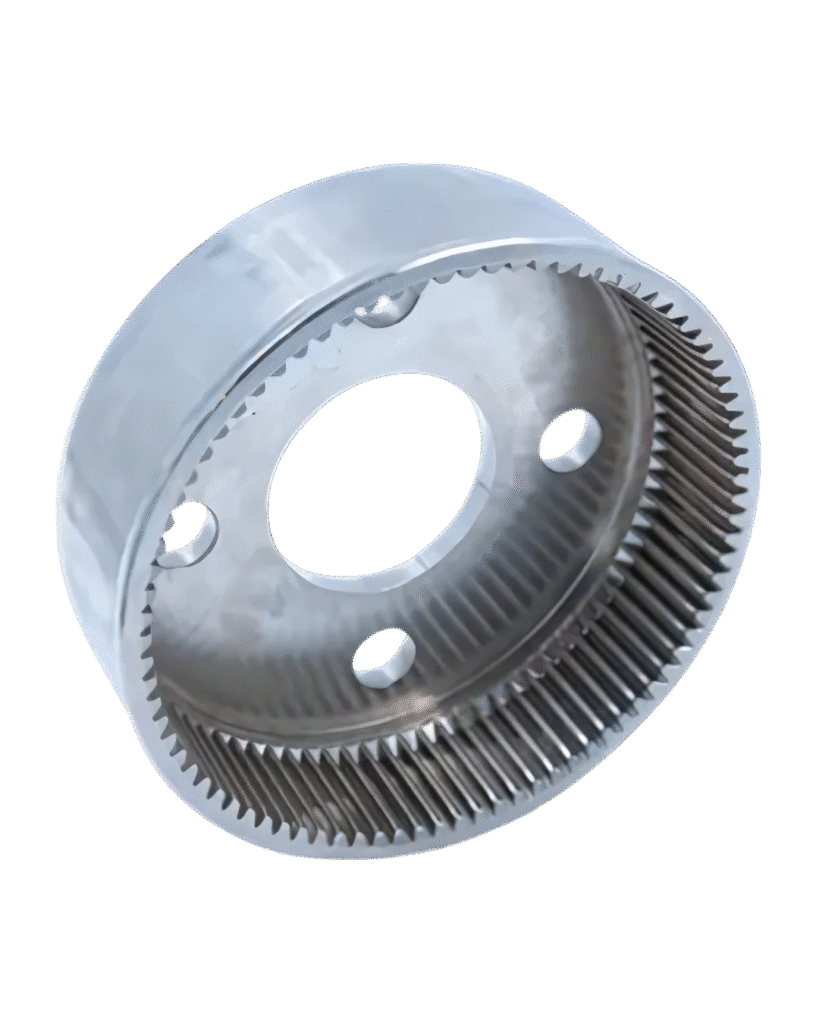

Flowforming With Internal Splines

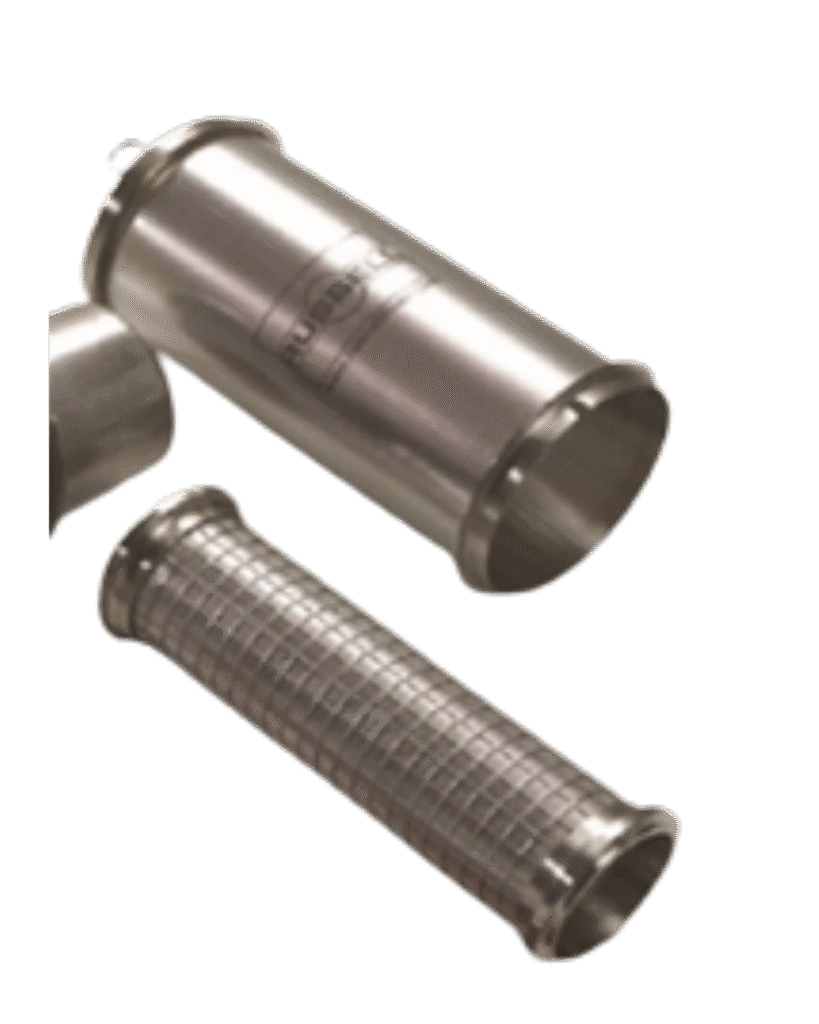

Flowforming of Cylindrical Tubes

Flowforming of Cylindrical Tubes

Metal Spinning

Flowforming with internal splines

Flowforming of cylindrical tubes

Shear forming

Metal spinning

About US

About Our Company

We are contract manufacturers of several critical products for various Defence & Aerospace organizations across the country. Our experience & expertise can be applied in many industries where precision & quality are of utmost importance.

FLOW FORMING & its Benefits section of the website offers clear understanding about the advantages of Flow Forming.

Flow Forming

Flow Forming is a cold forming process where material is moved into the desired shape rather than being removed or cut into the required shape, and with benefit of direct control over wall thickness. It offers tremendous advantages in terms of dimensional accuracies, improved Physical, Mechanical & Metallurgical properties along with material savings.

Forward Flow Forming, Reverse Flow Forming, Shear Forming & Flow Turning are all different techniques of Flow Forming, it is highly suitable for manufacturing high performance components in various industries such as Aerospace, Defence, Automotive, Oil & Gas, etc. Benefits of Flow Forming outweigh and are unparalleled when compared to any other metal forming processes.

Materials that are formable using Flow Forming process:

- Copper

- Aluminium

- Stainless Steel

- Inconel

- Nickel

- Maraging Steel

- Alloy Steel

- Titanium

- Brass

- Columbium

Competitive Pricing

Quality Product

Quick Delivery

01.

Competitive Pricing

Competitively priced when procured in bulk compared to other metal forming processes

02.

Quality Product

Assurance through multiple quality checks using certified calibrated instruments & properties testing at NABL accredited labs

03.

Quick Delivery

Commited towards promised delivery schedule

Benefits of Flow Forming

- Easy to obtain dimensional accuracies with very high precision

- Excellent control over wall thickness - varying or uniform

- In most cases even complex shapes can be formed in single operation

- High forming degree without the need for heat treatment

- Materials with very high tensile strengths can also be cold formed

- Excellent residual elongation values despite high forming degrees

- Superior and controlled Mechanical & Metallurgical properties

- Excellent surface finish

- Consistent repeatability over thousands of components using CNC control

- Economical for bulk quantities as material wastage is minimum

Defence

Aerospace

Oil & Gas

Automotive

Food Processing & Filtration

Flow Forming with internal splines

Flow Forming with internal splines

Flow forming of cylindrical tubes

Flow Forming of cylindrical tubes

Shear forming

Shear forming

Metal spinning

Metal spinning